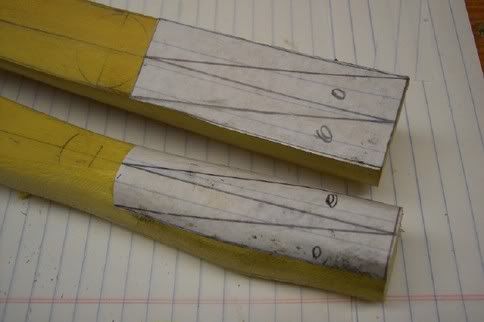

In the picture it looks like you have a pretty short area selected for your splice. I make my splices abut 3 3/4" long on each limb. With this length I can hide the complete splice under a 4" piece of handle leather, never had one come apart and have probably splice at least 75 pairs of billets together.

Don't worry about squaring the sides, flatten the belly so when you run the billet through your band saw it can't wobble around. If it does you will have one more sloppy splice that won't fit together very well..

I flatten the belly on a belt sander, then check how the belly and back alignment by putting the billet belly down on my band saw table and sighting down it from eye level. I don't want the back tilted to one side or the other.

Draw your splice on a piece of paper, cut the drawn splice pattern in two and glue it on your billet with Elmer's glue, matching the center line on your pattern with the center line on your bow, piece of cake.

In the picture I am replacing a broken limb on an already finished osage bow. Without the paper pattern it would be almost impossible to get an accurate cut on the already shaped riser.

This repair turned out pretty well.