now the epoxy has cured and I proceed to file the outside of the wood flush to the tang.

here we are flush all the way around.

next we profile the sides of the wood close to our desired handle shape using files and rasps.

here the handle is shaped close to my liking.

now its time to start sanding the handle using the hickory slat and various grits of paper.

after sanding to a 150 or 220 grit I like to burnish the wood with a piece of brown paper bag.

now its time for some finish.

I like Danish oil.

apply following the directions on the can.

after the Danish oil has dried I follow it up with 4-6 very light coats of tru-oil.

again following the directions on the bottle.

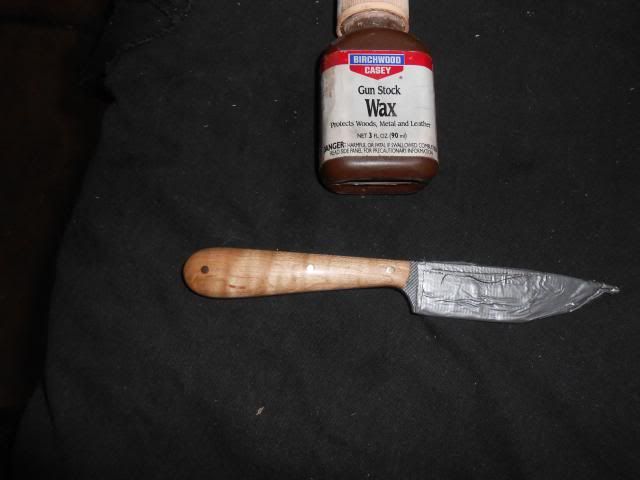

after the tru oil has dried I follow up with a couple coats of gunstock wax.

now its time to take off the tape and remove the residue.

after a little clean up we have a finished knife ready for leather.

that's about it folks!

I hope this encourages some of you to try this on your own.

Kevin