Don't give up

You will get there

Yes most folks use the side rather than the end of the bit

Different strokes for different Folks

If we all do everything the same we would be a boring lot for sure

Thank ya Guy,

. Well I finally got it working pretty good. I don't have calipers at the moment, but my outfeed hole was drilled with a 11/32 bit, so hopefully they are somewhere around there. I picked up a round over bit, and that seemed to do the trick just fine. My homemade spine tester only goes up to 75#, so they are somewhere over 75# is all I know, haha. At least the doug fir are. The ash seem a lot lighter in spine, I haven't tested any ash though. I do set the bit under the square stock and raise and lower to get the right thickness diameter, kind of off to the side and under, but it was not like my big anarchistic idea or anything, my router bit just kept falling in it's housing due to being to loose in the housing, so eventually when I was messing around with it, I got it working, and looked and somehow the bit was below the shaft, haha. I do know some people have did it that way from scouring the net though, this guy does apparently:

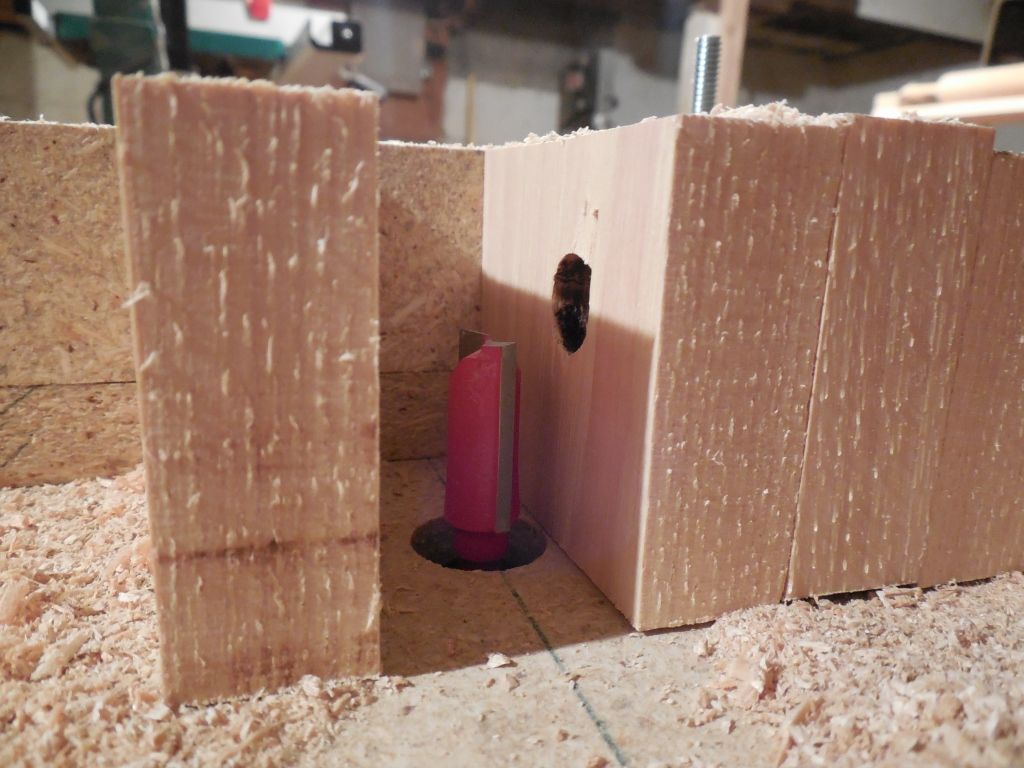

http://leatherwall.bowsite.com/TF/lw/thread2.cfm?threadid=215027&category=88Here's how I had it at when I was using it below the shaft, you can see the tip sticking over the edge a bit:

It was cutting ok (better than the pictured shafts), but giving me little scratches and horrible tear out in the douglas fir still:

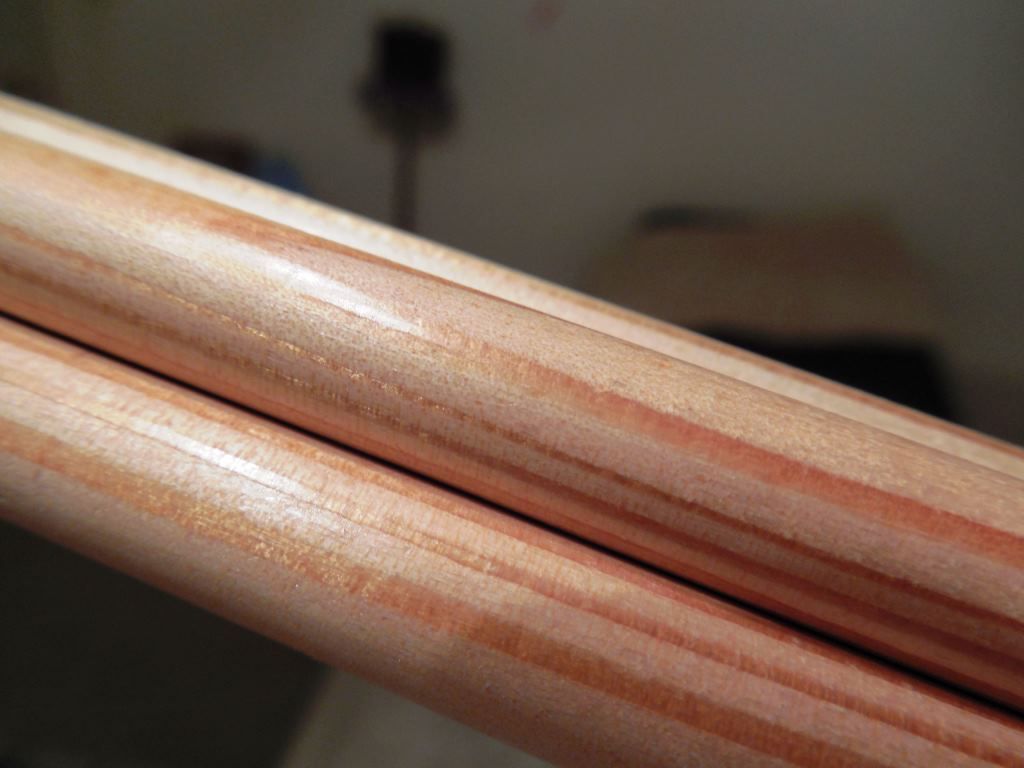

After putting a 1/4" round over bit in it tonight, my results were a lot better. This is what I am getting now:

If only they were not all spining too light for the bow I was wanting to make arrows for,

. So I guess the doug fir at 11/32 will need a good deal more sanding to reach around 45lbs or so, so the finish really don't matter anyway. I am quite happy I finally got this stuff cutting without tear out though. I tried cutting them using a jig similar to the 30 dollar veritas pencil sharpener thingy, tried using a bandsaw (and ruined two blades, the lenox carbide blade still has me kicking myself in the arse), and finally got something working on the cheapest router I could find. I am definitely a fan of the router for woods that tear out easy. I picked up a 5/16" bit too, so I guess I will make an arm for that diameter as well, as well as one for 1/2" shafts for warbows. This was a lot of fun, thank you everyone for the help, it is amply appreciated as always.